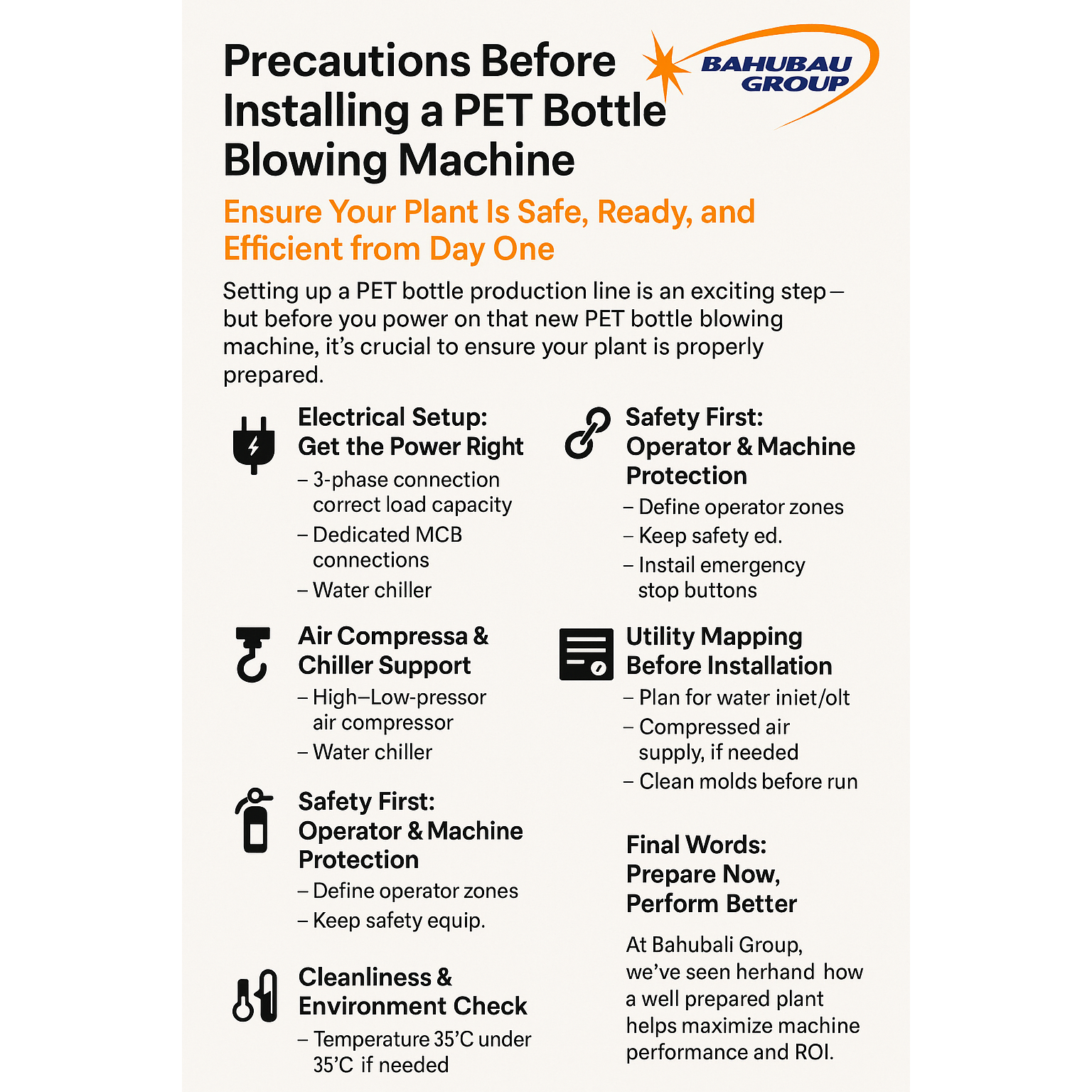

Ensure Your Plant Is Safe, Ready, and Efficient from Day One Setting up a PET bottle production line is an exciting step—but before you power on that new PET bottle blowing machine, it’s crucial to ensure your plant is properly prepared. Whether you're launching a mineral water bottling unit, Beverages or Soda bottle production line, or packaging for Other Industry, improper installation can lead to costly delays, machine damage, and operational inefficiencies. This blog covers all precautions you need to take before installing a plastic bottle blow molding machine, including technical readiness, utility planning, and safety protocols. ________________________________________ 🔌 1. Electrical Setup: Get the Power Right PET blowing machines, especially fully automatic blow moulding machines, demand consistent, high-capacity power. Ensure: • 3-phase connection with stabilizer • Correct load capacity as per machine size (15–40 kW) • Dedicated MCB connections and earthing • Separate panel for compressor, chiller, heater & blowing unit 💡 Tip: Use copper wiring and surge protection for uninterrupted performance. ________________________________________ 💨 2. Air Compressor & Chiller Support A PET bottle molding machine needs compressed air and cooling to operate smoothly. Checklist: • High- & Low-Pressure air compressor with 25 to 30 bar output • Air dryer and filters to remove moisture • Water chiller (3–10 TR) to maintain mold temperature • Leak-proof SS / GI pipelines or PU hoses Multi Cavity / Higher Production Machines like the 4 Cavity Automatic PET Bottle Making Machine or 6 cavity plastic bottle making machine will not function correctly without this support system in place. ________________________________________ 🏗️ 3. Floor, Foundation & Layout Before installation: • Floor must be level and vibration-free (avoid tile or soft surfaces) • Ensure at least 1000–2000 sq. ft. clear space • Keep room for preform storage, mould rack, and finished bottles • Leave aisle space for movement and cleaning 🔧 Don’t forget: All semi-automatic 50 to 5000ML bottle & jar making machines need easy front and side access. ________________________________________ 🧯 4. Safety First: Operator & Machine Protection • Define operator zones with floor tape • Keep a fire extinguisher, first-aid kit, and PPE gear (gloves, eyewear) • Install emergency stop buttons on all sides If installing a fully automatic PET bottle blowing machine, use protective guard rails and sensor-based doors for safety compliance. ________________________________________ 🔗 5. Mold & Tool Readiness Keep this kit ready: • Proper mould alignment tools • Anti-rust oil / Grease • Keep Every Mould Properly with its attachment • Clean worktable for mold handling • Small Table wise for tool operations This applies to pharma bottle making machines, water bottle making machines, and even PET jar bottle making machines. ________________________________________ 📋 6. Utility Mapping Before Installation Plan connections for: • Water inlet/outlet to chiller • Compressed air supply from compressor to blowing unit • Electric cabling Good planning helps you avoid tangled wires or crossed pipes that affect safety and serviceability. ________________________________________ 🧪 7. Cleanliness & Environment Check • Keep your blowing zone dust-free and dry • Temperature under 35°C ensures proper preform heating • Install ventilation fans or exhaust ducts if needed • Clean preforms and moulds before first run Even the best high-performance PET bottle blowing machines need a clean environment to deliver premium clarity bottles. ________________________________________ ✅ Final Words: Prepare Now, Perform Better At Bahubali Group, we’ve seen firsthand how a well-prepared plant helps maximize machine performance and ROI. Whether you’re installing a semi-automatic PET bottle blowing machine or a fully automated stretch blow molding system, these precautions ensure you start strong and avoid common setbacks. ________________________________________ 📞 Need Help with Plant Setup or Site Layout? We provide: • Customized installation drawings • Technical consultation for utilities • On-site supervision (on request) • Best-fit machine recommendations according your product 📲 Call / WhatsApp: +91-9322057408 / +91-9222712342 📩 Email: bahubaliblowingmachine@gmail.com 🌐 Website: www.bahubaliblowingmachine.com pet bottle blowing machine Pet Jar Bottle Making Machine bottle making machine Plastic Bottle Making Machine Water Bottle Making Machine Water Bottle Making Machines Pharma Bottle Making Machine 4 Cavity Plastic Bottle Making Machine Automatic Blow Molding Machine Mineral Water Bottle Making Machine Semi automatic 50 to 5000ML Bottle & Jar Making Machine Semi Automatic 5 Litre Jar & Bottle PET Bottle Blowing Machine 2 Cavity Automatic PET Bottle Making Machine Pet Blow Moulding Machines High Quality PET Blowing Machine Fully & Semi Automatic PET Bottle Blowing Machine Moulding Machine Automatic Blow Moulding Machine Fully Automatic Blow Moulding Machine PET bottle blowing machine Automatic PET bottle blowing machine Semi-automatic PET bottle blowing machine PET bottle blowing machine suppliers PET bottle machine manufacturers PET bottle molding machine PET bottle stretch blowing machine High-speed PET bottle blowing machine Blow molding machine for PET bottles Bottle blowing machine for packaging Blow molding machine manufacturers

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Precautions Before Installing a PET Bottle Blowing Machi...

2025-07-21T09:46:09

Ensure Your Plant Is Safe, Ready, and Efficient from Day One Setting up a PET bottle production line is an exciting step—but before you power on that new PET bottle blowing machine, it’s crucial to ensure your plant is properly prepared. Whether you're launching a mineral water bottling unit, Beverages or Soda bottle production line, or packaging for Other Industry, improper installation can lead to costly delays, machine damage, and operational inefficiencies. This blog covers all precautions you need to take before installing a plastic bottle blow molding machine, including technical readiness, utility planning, and safety protocols. ________________________________________ 🔌 1. Electrical Setup: Get the Power Right PET blowing machines, especially fully automatic blow moulding machines, demand consistent, high-capacity power. Ensure: • 3-phase connection with stabilizer • Correct load capacity as per machine size (15–40 kW) • Dedicated MCB connections and earthing • Separate panel for compressor, chiller, heater & blowing unit 💡 Tip: Use copper wiring and surge protection for uninterrupted performance. ________________________________________ 💨 2. Air Compressor & Chiller Support A PET bottle molding machine needs compressed air and cooling to operate smoothly. Checklist: • High- & Low-Pressure air compressor with 25 to 30 bar output • Air dryer and filters to remove moisture • Water chiller (3–10 TR) to maintain mold temperature • Leak-proof SS / GI pipelines or PU hoses Multi Cavity / Higher Production Machines like the 4 Cavity Automatic PET Bottle Making Machine or 6 cavity plastic bottle making machine will not function correctly without this support system in place. ________________________________________ 🏗️ 3. Floor, Foundation & Layout Before installation: • Floor must be level and vibration-free (avoid tile or soft surfaces) • Ensure at least 1000–2000 sq. ft. clear space • Keep room for preform storage, mould rack, and finished bottles • Leave aisle space for movement and cleaning 🔧 Don’t forget: All semi-automatic 50 to 5000ML bottle & jar making machines need easy front and side access. ________________________________________ 🧯 4. Safety First: Operator & Machine Protection • Define operator zones with floor tape • Keep a fire extinguisher, first-aid kit, and PPE gear (gloves, eyewear) • Install emergency stop buttons on all sides If installing a fully automatic PET bottle blowing machine, use protective guard rails and sensor-based doors for safety compliance. ________________________________________ 🔗 5. Mold & Tool Readiness Keep this kit ready: • Proper mould alignment tools • Anti-rust oil / Grease • Keep Every Mould Properly with its attachment • Clean worktable for mold handling • Small Table wise for tool operations This applies to pharma bottle making machines, water bottle making machines, and even PET jar bottle making machines. ________________________________________ 📋 6. Utility Mapping Before Installation Plan connections for: • Water inlet/outlet to chiller • Compressed air supply from compressor to blowing unit • Electric cabling Good planning helps you avoid tangled wires or crossed pipes that affect safety and serviceability. ________________________________________ 🧪 7. Cleanliness & Environment Check • Keep your blowing zone dust-free and dry • Temperature under 35°C ensures proper preform heating • Install ventilation fans or exhaust ducts if needed • Clean preforms and moulds before first run Even the best high-performance PET bottle blowing machines need a clean environment to deliver premium clarity bottles. ________________________________________ ✅ Final Words: Prepare Now, Perform Better At Bahubali Group, we’ve seen firsthand how a well-prepared plant helps maximize machine performance and ROI. Whether you’re installing a semi-automatic PET bottle blowing machine or a fully automated stretch blow molding system, these precautions ensure you start strong and avoid common setbacks. ________________________________________ 📞 Need Help with Plant Setup or Site Layout? We provide: • Customized installation drawings • Technical consultation for utilities • On-site supervision (on request) • Best-fit machine recommendations according your product 📲 Call / WhatsApp: +91-9322057408 / +91-9222712342 📩 Email: bahubaliblowingmachine@gmail.com 🌐 Website: www.bahubaliblowingmachine.com pet bottle blowing machine Pet Jar Bottle Making Machine bottle making machine Plastic Bottle Making Machine Water Bottle Making Machine Water Bottle Making Machines Pharma Bottle Making Machine 4 Cavity Plastic Bottle Making Machine Automatic Blow Molding Machine Mineral Water Bottle Making Machine Semi automatic 50 to 5000ML Bottle & Jar Making Machine Semi Automatic 5 Litre Jar & Bottle PET Bottle Blowing Machine 2 Cavity Automatic PET Bottle Making Machine Pet Blow Moulding Machines High Quality PET Blowing Machine Fully & Semi Automatic PET Bottle Blowing Machine Moulding Machine Automatic Blow Moulding Machine Fully Automatic Blow Moulding Machine PET bottle blowing machine Automatic PET bottle blowing machine Semi-automatic PET bottle blowing machine PET bottle blowing machine suppliers PET bottle machine manufacturers PET bottle molding machine PET bottle stretch blowing machine High-speed PET bottle blowing machine Blow molding machine for PET bottles Bottle blowing machine for packaging Blow molding machine manufacturers

2025-07-21T09:46:09

Keywords

- PET bottle production environment check

- PET bottle blow molding machine suppliers

- PET bottle manufacturing plant safety

- High-capacity PET blow molding machines

- PET bottle production line installation

- Utility planning for PET machines

- Plant safety and safety protocols

- PET bottle mold and tool readiness

- Automatic PET bottle blowing machine

- PET bottle blowing machine setup

Submit Your Enquiry